Are you interested in learning about carbon filter cartridge making machines? In this guide, I will provide you with valuable information on the process of manufacturing carbon filter cartridges and the necessary skills to operate these machines effectively.

The Process of Carbon Filter Cartridge Making

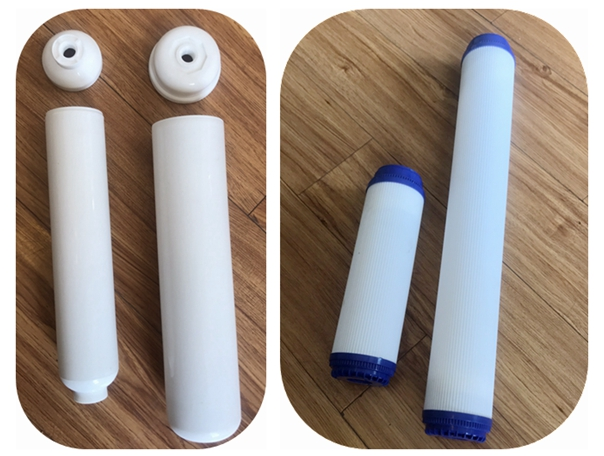

To create high-quality carbon filter cartridges, a specialized machine is required. These machines are designed to efficiently produce filters that effectively remove impurities from water or air. The process involves several steps such as material preparation, molding, curing, and testing.

In the material preparation stage, activated carbon particles are mixed with binders and additives to form a homogeneous mixture. This mixture is then fed into the machine’s hopper for further processing.

The next step is molding, where the prepared mixture is compressed using hydraulic pressure or other mechanical methods. This compression ensures that the particles adhere together firmly and maintain their shape during use.

After molding, the cartridges undergo a curing process where they are heated at specific temperatures for a predetermined period. This helps strengthen the structure of the filters and enhances their filtration capabilities.

Finally, each cartridge goes through rigorous testing procedures to ensure its quality meets industry standards. These tests include flow rate measurement, pressure resistance assessment, and efficiency evaluation.

Hongteng: A Leading Manufacturer of Carbon Filter Cartridge Making Machines

Hongteng is renowned for producing top-of-the-line carbon filter cartridge making machines. With years of experience in this field, Hongteng has perfected its technology to deliver reliable and efficient equipment for manufacturers worldwide.

Their machines feature advanced automation systems that streamline production processes while maintaining precision and consistency in every step. Additionally, Hongteng provides comprehensive technical support and training programs to assist operators in maximizing the machine’s potential.

By choosing Hongteng as your supplier, you can trust that their carbon filter cartridge making machines will meet your production needs and contribute to the success of your business.

The Spun Filter Cartridge Manufacturing Machine

In addition to carbon filter cartridge making machines, there is another type of equipment called spun filter cartridge manufacturing machines. These machines are specifically designed for producing spun filters, which are widely used for various filtration applications.

The process involves spinning a continuous filament of polypropylene or other materials onto a core, creating a tightly wound structure with excellent filtration capabilities. The spun filter cartridges produced by these machines offer high dirt-holding capacity and low pressure drop.

Spun filter cartridge manufacturing machines utilize advanced technology to ensure precise control over the winding process. They also incorporate features such as automatic cutting and sealing mechanisms, further enhancing efficiency and productivity.

Conclusion

In conclusion, carbon filter cartridge making machines play a crucial role in producing effective filtration solutions for water and air purification. Understanding the process involved in manufacturing these cartridges and having access to reliable machinery like those offered by Hongteng is essential for successful production operations.

By acquiring the necessary skills and knowledge in operating these machines effectively, manufacturers can provide high-quality carbon filter cartridges that meet industry standards while meeting customer demands for clean and purified environments.